-

Email:

info@unitgrease.com -

Call Us:

+91 98990 06662

Lubricating greases have traditionally been used to keep automotive & industrialmachinesand their components lubricated at all times.

A good quality lubricating grease should:

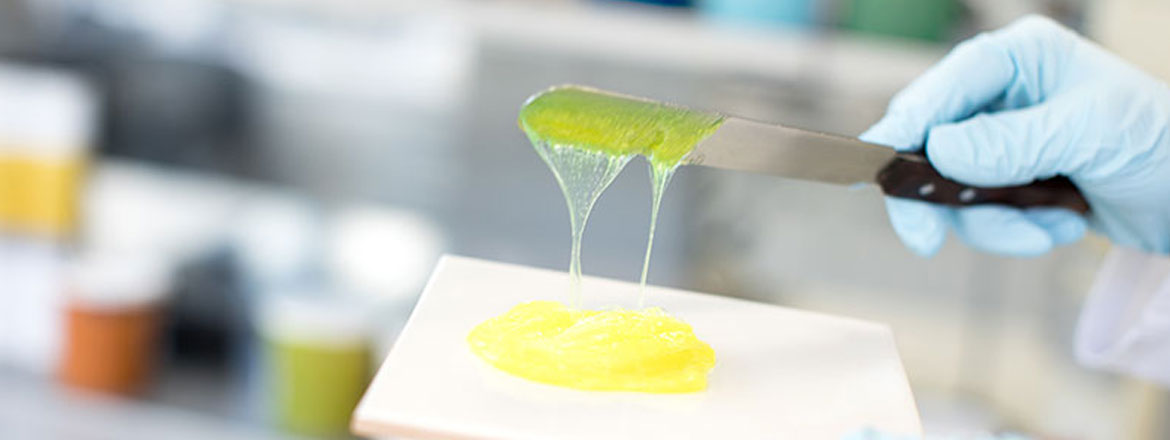

Lubricating greases are manufactured by adding 5% - 15% of a thickener and additives into a lube base oil. In Short, GREASE = BASE OIL + ADDITIVES + THICKENER

BASE OILS

The base oil performs the actual lubrication and its type determines the overall performance of the grease. Below are different types of base oils used in grease manufacturing. Castor Oils.

The majority of greases in the market are composed of mineral oil blended with a soap thickener.

THICKENERS

The thickeners in grease absorb lubebase oil and additives like a sponge and release them when under pressure.The lubricants prevent friction and create a barrier or film between moving parts without leaking out under the force of gravity or being squeezed out under pressure.

The primary type of thickeners typically includes lithium, calcium, clay, polyurea, and sodium. Different thickeners have different performance characteristics, for example, temperature, load, moisture/water pressure, etc. These factors are to be taken into account when choosing the right thickener for grease.

ADDITIVES

The additives are added to enhance the performance of the grease. For example, extreme pressure additives enhance the load-carrying capacity of the grease.

Types of grease additives:

To summarise,it is extremely important to consider all of the above components i.e., Base Oil, soap & additives that makeup grease before making a final decisionto lubricate any type of equipment.

ERPLuDTfijA

-sVrqvtfKgFBmES